New volumes of the Encyclopædia Britannica > Volume 30, K-MOR

(197) Page 173

Download files

Complete book:

Individual page:

Thumbnail gallery: Grid view | List view

LEAD

173

produced. This is drawn off, cooled and filtered, and

forms a white paint of good body, consisting of about 65

per cent, lead sulphate, 26 per cent, lead oxide, 6 per

cent, zinc oxide, and 3 per cent, other substance. Thus in

the Mofiett method it is no matter whether metal or fume

is produced, as in either case it is saved and the price is

about the same.

In smelting at once in the same blast-furnace ores of

different character, the old use of separate processes of pre¬

cipitation, roasting and reduction, and general reduction

prevailing in the Harz Mountains (see Ency. Brit. vol. xiv.

p. 376), Freiberg, and other places, to suit local conditions,

has had to be abandoned. Ores are smelted raw if the fall

of matte (metallic sulphide) does not exceed 5 per cent. ;

otherwise they are subjected to a preliminary oxidizing

roast to expel the sulphur, unless they run too high in

silver, say 100 ounces to the ton, when they are smelted

raw. The leading reverberatory furnace for roasting lead¬

bearing sulphide ores has a level hearth 14-16 feet wide and

60-80 feet long. It puts through 9-12 tons of ore in twenty-

four hours, reducing the percentage of sulphur to 2-4 per

cent., and requires four to six men and about two tons

of coal. In many instances it has been replaced by

mechanical furnaces, which are now very common in roast¬

ing sulphide copper ores. (See Acid and Alkali Manu-

factuee.) A modern blast-furnace is oblong in hori¬

zontal section and about 24 feet high from furnace

floor to feed floor. The shaft, resting upon arches sup¬

ported by four cast-iron columns about 9 feet high, is

usually of brick, red brick on the outside, fire-brick on the

inside; sometimes it is made of wrought-iron water-

jackets. The smelting zone always has a bosh and a con¬

tracted tuyere section. It is enclosed by water-jackets,

which are usually cast-iron, sometimes mild steel. The

hearth always has an Arents siphon tap. This is an

inclined channel running through the side-wall, beginning

near the bottom of the crucible and ending at the top of

the hearth, where it is enlarged into a basin. The crucible

and the channel form the two limbs of an inverted siphon.

While the furnace is running the crucible and channel

remain filled with lead; all the lead reduced to the

metallic state in smelting collects in the crucible, and rising

in the channel, overflow's into the basin, whence it is removed.

The slag and matte formed float upon the lead in the crucible

and are tapped, usually together, at intervals into slag-

pots, where the heavy matte settles on the bottom and

the light slag on the top. When cold they are readily

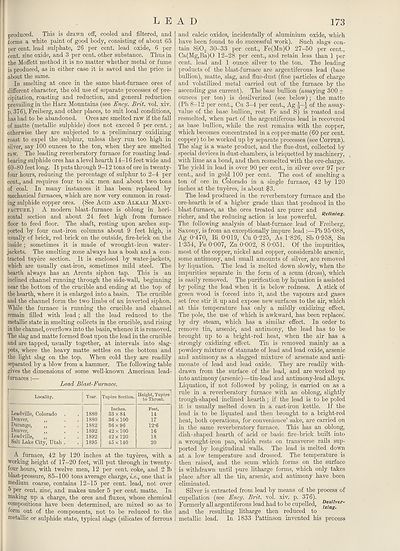

separated by a blow from a hammer. The following table

gives the dimensions of some well-known American lead-

furnaces :—

Lead Blast-Furnace.

Locality.

Leadville, Colorado

Denver, ,,

Durango, ,,

Denver, ,,

Leadville, ,,

Salt Lake City, Utali

Year.

1880

1880

1882

1892

1892

1895

Tuyere Section. ““fW™

Inches.

33x84

36x100

36x96

42 x 100

42 x 120

45 x 140

Feet.

14

17

12-6

16

18

20

A furnace, 42 by 120 inches at the tuyeres, with a

working height of 17-20 feet, will put through in twenty-

four hours, wdth twelve men, 12 per cent, coke, and 2 5)

blast-pressure, 85-100 tons average charge, i.e., one that is

medium coarse, contains 12-15 per cent, lead, not over

5 per cent, zinc, and makes under 5 per cent, matte. In

making up a charge, the ores and fluxes, whose chemical

compositions have been determined, are mixed so as to

form out of the components, not to be reduced to the

metallic or sulphide state, typical slags (silicates of ferrous

and calcic oxides, incidentally of aluminium oxide, which

have been found to do successful w’ork). Such slags con¬

tain Si02 30-33 per cent., Fe(Mn)0 27-50 per cent.,

Ca(Mg,Ba)0 12-28 per cent., and retain less than 1 per

cent, lead and 1 ounce silver to the ton. The leading

products of the blast-furnace are argentiferous lead (base

bullion), matte, slag, and flue-dust (fine particles of charge

and volatilized metal carried out of the furnace by the

ascending gas current). The base bullion (assaying 300 ±

ounces per ton) is desilverized (see below); the matte

(Pb 8-12 per cent., Cu 3-4 per cent., Ag of the assay-

value of the base bullion, rest Fe and S) is roasted and

resmelted, when part of the argentiferous lead is recovered

as base bullion, while the rest remains with the copper,

which becomes concentrated in a copper-matte (60 per cent,

copper) to be worked up by separate processes (see Copper).

The slag is a waste product, and the flue-dust, collected by

special devices in dust-chambers, is briquetted by machinery,

with lime as a bond, and then resmelted with the ore-charge.

The yield in lead is over 90 per cent., in silver over 97 per

cent., and in gold 100 per cent. The cost of smelting a

ton of ore in Colorado in a single furnace, 42 by 120

inches at the tuyeres, is about $3.

The lead produced in the reverberatory furnace and the

ore-hearth is of a higher grade than that produced in the

blast-furnace, as the ores treated are purer and

richer, and the reducing action is less powerful. Reflnlng-

The following analysis of blast-furnace lead of Freiberg,

Saxony, is from an exceptionally impure lead :—Pb 95'088,

Ag 0-470, Bi 0-019, Cu 0*225, As 1-826, Sb 0-958, Sn

1"354, Fe 0"007, Zn 0‘002, S 0"051. Of the impurities,

most of the copper, nickel and copper, considerable arsenic,

some antimony, and small amounts of silver, are removed

by liquation. The lead is melted down slowly, when the

impurities separate in the form of a scum (dross), which

is easily removed. The purification by liquation is assisted

by poling the lead when it is below redness. A stick of

green wood is forced into it, and the vapours and gases

set free stir it up and expose new surfaces to the air, which

at this temperature has only a mildly oxidizing effect.

The pole, the use of which is awkward, has been replaced

by dry steam, which has a similar effect. In order to

remove tin, arsenic, and antimony, the lead has to be

brought up to a bright-red heat, when the air has a

strongly oxidizing effect. Tin is removed mainly as a

powdery mixture of stannate of lead and lead oxide, arsenic

and antimony as a slagged mixture of arsenate and anti-

monate of lead and lead oxide. They are readily with¬

drawn from the surface of the lead, and are worked up

into antimony (arsenic)—tin-lead and antimony-lead alloys.

Liquation, if not followed by poling, is carried on as a

rule in a reverberatory furnace with an oblong, slightly

trough-shaped inclined hearth; if the lead is to be poled

it is usually melted down in a cast-iron kettle. If the

lead is to be liquated and then brought to a bright-red

heat, both operations, for convenience’ sake, are carried on

in the same reverberatory furnace. This has an oblong,

dish-shaped hearth of acid or basic fire-brick built into

a wrought-iron pan, which rests on transverse rails sup¬

ported by longitudinal walls. The lead is melted down

at a low temperature and drossed. The temperature is

then raised, and the scum which forms on the surface

is withdrawn until pure litharge forms, which only takes

place after all the tin, arsenic, and antimony have been

eliminated.

Silver is extracted from lead by means of the process of

cupellation (see Ency. Brit. vol. xiv. p. 376).

Formerly all argentiferous lead had to be cupelled, ^.^ver‘

and the resulting litharge then reduced to

metallic lead. In 1833 Pattinson invented his process

173

produced. This is drawn off, cooled and filtered, and

forms a white paint of good body, consisting of about 65

per cent, lead sulphate, 26 per cent, lead oxide, 6 per

cent, zinc oxide, and 3 per cent, other substance. Thus in

the Mofiett method it is no matter whether metal or fume

is produced, as in either case it is saved and the price is

about the same.

In smelting at once in the same blast-furnace ores of

different character, the old use of separate processes of pre¬

cipitation, roasting and reduction, and general reduction

prevailing in the Harz Mountains (see Ency. Brit. vol. xiv.

p. 376), Freiberg, and other places, to suit local conditions,

has had to be abandoned. Ores are smelted raw if the fall

of matte (metallic sulphide) does not exceed 5 per cent. ;

otherwise they are subjected to a preliminary oxidizing

roast to expel the sulphur, unless they run too high in

silver, say 100 ounces to the ton, when they are smelted

raw. The leading reverberatory furnace for roasting lead¬

bearing sulphide ores has a level hearth 14-16 feet wide and

60-80 feet long. It puts through 9-12 tons of ore in twenty-

four hours, reducing the percentage of sulphur to 2-4 per

cent., and requires four to six men and about two tons

of coal. In many instances it has been replaced by

mechanical furnaces, which are now very common in roast¬

ing sulphide copper ores. (See Acid and Alkali Manu-

factuee.) A modern blast-furnace is oblong in hori¬

zontal section and about 24 feet high from furnace

floor to feed floor. The shaft, resting upon arches sup¬

ported by four cast-iron columns about 9 feet high, is

usually of brick, red brick on the outside, fire-brick on the

inside; sometimes it is made of wrought-iron water-

jackets. The smelting zone always has a bosh and a con¬

tracted tuyere section. It is enclosed by water-jackets,

which are usually cast-iron, sometimes mild steel. The

hearth always has an Arents siphon tap. This is an

inclined channel running through the side-wall, beginning

near the bottom of the crucible and ending at the top of

the hearth, where it is enlarged into a basin. The crucible

and the channel form the two limbs of an inverted siphon.

While the furnace is running the crucible and channel

remain filled with lead; all the lead reduced to the

metallic state in smelting collects in the crucible, and rising

in the channel, overflow's into the basin, whence it is removed.

The slag and matte formed float upon the lead in the crucible

and are tapped, usually together, at intervals into slag-

pots, where the heavy matte settles on the bottom and

the light slag on the top. When cold they are readily

separated by a blow from a hammer. The following table

gives the dimensions of some well-known American lead-

furnaces :—

Lead Blast-Furnace.

Locality.

Leadville, Colorado

Denver, ,,

Durango, ,,

Denver, ,,

Leadville, ,,

Salt Lake City, Utali

Year.

1880

1880

1882

1892

1892

1895

Tuyere Section. ““fW™

Inches.

33x84

36x100

36x96

42 x 100

42 x 120

45 x 140

Feet.

14

17

12-6

16

18

20

A furnace, 42 by 120 inches at the tuyeres, with a

working height of 17-20 feet, will put through in twenty-

four hours, wdth twelve men, 12 per cent, coke, and 2 5)

blast-pressure, 85-100 tons average charge, i.e., one that is

medium coarse, contains 12-15 per cent, lead, not over

5 per cent, zinc, and makes under 5 per cent, matte. In

making up a charge, the ores and fluxes, whose chemical

compositions have been determined, are mixed so as to

form out of the components, not to be reduced to the

metallic or sulphide state, typical slags (silicates of ferrous

and calcic oxides, incidentally of aluminium oxide, which

have been found to do successful w’ork). Such slags con¬

tain Si02 30-33 per cent., Fe(Mn)0 27-50 per cent.,

Ca(Mg,Ba)0 12-28 per cent., and retain less than 1 per

cent, lead and 1 ounce silver to the ton. The leading

products of the blast-furnace are argentiferous lead (base

bullion), matte, slag, and flue-dust (fine particles of charge

and volatilized metal carried out of the furnace by the

ascending gas current). The base bullion (assaying 300 ±

ounces per ton) is desilverized (see below); the matte

(Pb 8-12 per cent., Cu 3-4 per cent., Ag of the assay-

value of the base bullion, rest Fe and S) is roasted and

resmelted, when part of the argentiferous lead is recovered

as base bullion, while the rest remains with the copper,

which becomes concentrated in a copper-matte (60 per cent,

copper) to be worked up by separate processes (see Copper).

The slag is a waste product, and the flue-dust, collected by

special devices in dust-chambers, is briquetted by machinery,

with lime as a bond, and then resmelted with the ore-charge.

The yield in lead is over 90 per cent., in silver over 97 per

cent., and in gold 100 per cent. The cost of smelting a

ton of ore in Colorado in a single furnace, 42 by 120

inches at the tuyeres, is about $3.

The lead produced in the reverberatory furnace and the

ore-hearth is of a higher grade than that produced in the

blast-furnace, as the ores treated are purer and

richer, and the reducing action is less powerful. Reflnlng-

The following analysis of blast-furnace lead of Freiberg,

Saxony, is from an exceptionally impure lead :—Pb 95'088,

Ag 0-470, Bi 0-019, Cu 0*225, As 1-826, Sb 0-958, Sn

1"354, Fe 0"007, Zn 0‘002, S 0"051. Of the impurities,

most of the copper, nickel and copper, considerable arsenic,

some antimony, and small amounts of silver, are removed

by liquation. The lead is melted down slowly, when the

impurities separate in the form of a scum (dross), which

is easily removed. The purification by liquation is assisted

by poling the lead when it is below redness. A stick of

green wood is forced into it, and the vapours and gases

set free stir it up and expose new surfaces to the air, which

at this temperature has only a mildly oxidizing effect.

The pole, the use of which is awkward, has been replaced

by dry steam, which has a similar effect. In order to

remove tin, arsenic, and antimony, the lead has to be

brought up to a bright-red heat, when the air has a

strongly oxidizing effect. Tin is removed mainly as a

powdery mixture of stannate of lead and lead oxide, arsenic

and antimony as a slagged mixture of arsenate and anti-

monate of lead and lead oxide. They are readily with¬

drawn from the surface of the lead, and are worked up

into antimony (arsenic)—tin-lead and antimony-lead alloys.

Liquation, if not followed by poling, is carried on as a

rule in a reverberatory furnace with an oblong, slightly

trough-shaped inclined hearth; if the lead is to be poled

it is usually melted down in a cast-iron kettle. If the

lead is to be liquated and then brought to a bright-red

heat, both operations, for convenience’ sake, are carried on

in the same reverberatory furnace. This has an oblong,

dish-shaped hearth of acid or basic fire-brick built into

a wrought-iron pan, which rests on transverse rails sup¬

ported by longitudinal walls. The lead is melted down

at a low temperature and drossed. The temperature is

then raised, and the scum which forms on the surface

is withdrawn until pure litharge forms, which only takes

place after all the tin, arsenic, and antimony have been

eliminated.

Silver is extracted from lead by means of the process of

cupellation (see Ency. Brit. vol. xiv. p. 376).

Formerly all argentiferous lead had to be cupelled, ^.^ver‘

and the resulting litharge then reduced to

metallic lead. In 1833 Pattinson invented his process

Set display mode to:

![]() Universal Viewer |

Universal Viewer | ![]() Mirador |

Large image | Transcription

Mirador |

Large image | Transcription

Images and transcriptions on this page, including medium image downloads, may be used under the Creative Commons Attribution 4.0 International Licence unless otherwise stated. ![]()

| Encyclopaedia Britannica > New volumes of the Encyclopædia Britannica > Volume 30, K-MOR > (197) Page 173 |

|---|

| Permanent URL | https://digital.nls.uk/193570062 |

|---|

| Attribution and copyright: |

|

|---|---|

| Shelfmark | EB.18 |

|---|---|

| Description | Ten editions of 'Encyclopaedia Britannica', issued from 1768-1903, in 231 volumes. Originally issued in 100 weekly parts (3 volumes) between 1768 and 1771 by publishers: Colin Macfarquhar and Andrew Bell (Edinburgh); editor: William Smellie: engraver: Andrew Bell. Expanded editions in the 19th century featured more volumes and contributions from leading experts in their fields. Managed and published in Edinburgh up to the 9th edition (25 volumes, from 1875-1889); the 10th edition (1902-1903) re-issued the 9th edition, with 11 supplementary volumes. |

|---|---|

| Additional NLS resources: |

|