New volumes of the Encyclopædia Britannica > Volume 30, K-MOR

(198) Page 174

Download files

Complete book:

Individual page:

Thumbnail gallery: Grid view | List view

LEAD

174

(ibid. p. 377) by means of which practically all the silver

is concentrated in 13 per cent, of the original lead to be

cupelled, while the rest becomes market lead. In 1842

Karsten (loc. cit.) discovered that lead could be desilverized

by means of zinc. His invention, however, only took prac¬

tical form in 1850-52 through the researches of Parkes,

who showed how the zinc-silver-lead alloy formed could

be worked, and the desilverized lead freed from the zinc it

had taken up. In the Parkes process only 5 per cent, of

the original lead need be cupelled. Thus, while cupella-

tion still furnishes the only means for the final separation

of lead and silver, it has become an auxiliary process to

the two methods of concentration given. Of these the

Pattinson process has become subordinate to the Parkes

process, as it is more expensive and leaves more silver and

impurities in the market lead. It holds its own, however,

when base bullion contains bismuth in appreciable amounts

as in the Pattinson process bismuth follows the lead to be

cupelled, while in the Parkes process it remains with the

desilverized lead which goes to market, and lead of com¬

merce should contain little bismuth. At Freiberg, Saxony,

the two processes have been combined. The base bullion

is imperfectly Pattinsonized, giving lead rich in silver and

bismuth, which is cupelled, and lead low in silver, and

especially so in bismuth, which is further desilverized by

the Parkes process.

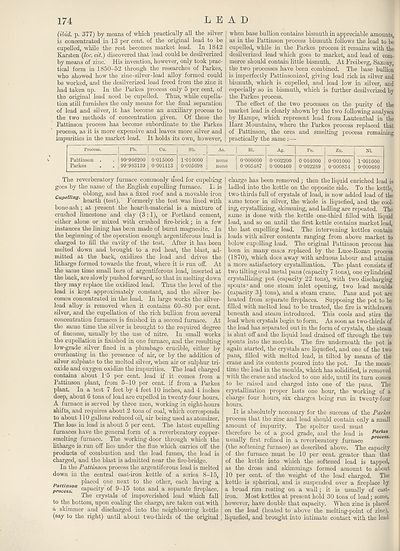

The effect of the two processes on the purity of the

market lead is clearly shown by the two following analyses

by Hampe, which represent lead from Lautenthal in the

Harz Mountains, where the Parkes process replaced that

of Pattinson, the ores and smelting process remaining

practically the same :—

Pb.

Pattinson

Parkes

99-966200

99-983139

Cu.

0-015000

0-001413

Sb.

1-010000

0-005698

Bi.

none

none

0-000600

0-005487

0-002200

0-000460

Fe.

0-004000

0-002289

Zii.

o-ooiooo

0-000834

1-001000

0-000680

The reverberatory furnace commonly used for cupelling

goes by the name of the English cupelling furnace. H is

oblong, and has a fixed roof and a movable iron

upe ' hearth (test). Formerly the test was lined with

bone-ash; at present the hearth-material is a mixture of

crushed limestone and clay (3:1), or Portland cement,

either alone or mixed with crushed fire-brick; in a few

instances the lining has been made of burnt magnesite. In

the beginning of the operation enough argentiferous lead is

charged to fill the cavity of the test. After it has been

melted down and brought to a red heat, the blast, ad¬

mitted at the back, oxidizes the lead and drives the

litharge formed towards the front, where it is run off. At

the same time small bars of argentiferous lead, inserted at

the back, are slowly pushed forward, so that in melting down

they may replace the oxidized lead. Thus the level of the

lead is kept approximately constant, and the silver be¬

comes concentrated in the lead. In large works the silver-

lead alloy is removed when it contains 60-80 per cent,

silver, and the cupellation of the rich bullion from several

concentration furnaces is finished in a second furnace. At

the same time the silver is brought to the required degree

of fineness, usually by the use of nitre. In small works

the cupellation is finished in one furnace, and the resulting

low-grade silver fined in a plumbago crucible, either by

overheating in the presence of air, or by the addition of

silver sulphate to the melted silver, when air or sulphur tri¬

oxide and oxygen oxidize the impurities. The lead charged

contains about F5 per cent, lead if it comes from a

Pattinson plant, from 5-10 per cent, if from a Parkes

plant. In a test 7 feet by 4 feet 10 inches, and 4 inches

deep, about 6 tons of lead are cupelled in twenty-four hours.

A furnace is served by three men, working in eight-hours

shifts, and requires about 2 tons of coal, which corresponds

to about 110 gallons reduced oil, air being used as atomizer.

The loss in lead is about 5 per cent. The latest cupelling

furnaces have the general form of a reverberatory copper-

smelting furnace. The working door through which the

litharge is.run off lies under the flue which carries off the

products of combustion and the lead fumes, the lead is

charged, and the blast is admitted near the fire-bridge.

In the Pattinson process the argentiferous lead is melted

down in the central cast-iron kettle of a series 8-15,

placed one next to the other, each having a

process?0 caPaci-ty °f 9-15 tons and a separate fireplace.

The crystals of impoverished lead which fall

to the bottom, upon coaling the charge, are taken out with

a skimmer and discharged into the neighbouring kettle

(say to the right) until about two-thirds of the original

charge has been removed ; then the liquid enriched lead is

ladled into the kettle on the opposite side. To the kettle,

two-thirds full of crystals of lead, is now added lead of the

same tenor in silver, the whole is liquefied, and the cool¬

ing, crystallizing, skimming, and ladling are repeated. The

same is done with the kettle one-third filled with liquid

lead, and so on until the first kettle contains market lead,

the last cupelling lead. The intervening kettles contain

leads with silver contents ranging from above market to

below cupelling lead. The original Pattinson process has

been in many cases replaced by the Luce-Rozan process

(1870), which does away with arduous labour and attains

a more satisfactory crystallization. The plant consists of

two tilting oval metal pans (capacity 7 tons), one cylindrical

crystallizing pot (capacity 22 tons), with two discharging

spouts * and one steam inlet opening, two lead moulds

(capacity 3| tons), and a steam crane. Pans and pot are

heated from separate fireplaces. Supposing the pot to be

filled with melted lead to be treated, the fire is withdrawn

beneath and steam introduced. This cools and stirs the

lead when crystals begin to form. As soon as two-thirds of

the lead has separated out in the form of crystals, the steam

is shut off and the liquid lead drained off through the two

spouts into the moulds. The fire underneath the pot is

again started, the crystals are liquefied, and one of the two

pans, filled with melted lead, is tilted by means of the

crane and its contents poured into the pot. In the mean¬

time the lead in the moulds, which has solidified, is removed

with the crane and stacked to one side, until its turn comes

to be raised and charged into one of the pans. The

crystallization proper lasts one hour, the working of a

charge four hours, six charges being run in twenty-four

hours.

It is absolutely necessary for the success of the Parkes

process that the zinc and lead should contain only a small

amount of impurity. The spelter used must

therefore be of a good grade, and the lead is Parkes

usually first refined in a reverberatory furnace Process’

(the softening furnace) as described above. The capacity

of the furnace must be 10 per cent, greater than that

of the kettle into which the softened lead is tapped,

as the dross and skimmings formed amount to about

10 per cent, of the weight of the lead charged. The

kettle is spherical, and is suspended over a fireplace by

a broad rim resting on a wall; it is usually of cast-

iron. Most kettles at present hold 30 tons of lead; some,

however, have double that capacity. When zinc is placed

on the lead (heated to above the melting-point of zinc),

liquefied, and brought into intimate contact with the lead

174

(ibid. p. 377) by means of which practically all the silver

is concentrated in 13 per cent, of the original lead to be

cupelled, while the rest becomes market lead. In 1842

Karsten (loc. cit.) discovered that lead could be desilverized

by means of zinc. His invention, however, only took prac¬

tical form in 1850-52 through the researches of Parkes,

who showed how the zinc-silver-lead alloy formed could

be worked, and the desilverized lead freed from the zinc it

had taken up. In the Parkes process only 5 per cent, of

the original lead need be cupelled. Thus, while cupella-

tion still furnishes the only means for the final separation

of lead and silver, it has become an auxiliary process to

the two methods of concentration given. Of these the

Pattinson process has become subordinate to the Parkes

process, as it is more expensive and leaves more silver and

impurities in the market lead. It holds its own, however,

when base bullion contains bismuth in appreciable amounts

as in the Pattinson process bismuth follows the lead to be

cupelled, while in the Parkes process it remains with the

desilverized lead which goes to market, and lead of com¬

merce should contain little bismuth. At Freiberg, Saxony,

the two processes have been combined. The base bullion

is imperfectly Pattinsonized, giving lead rich in silver and

bismuth, which is cupelled, and lead low in silver, and

especially so in bismuth, which is further desilverized by

the Parkes process.

The effect of the two processes on the purity of the

market lead is clearly shown by the two following analyses

by Hampe, which represent lead from Lautenthal in the

Harz Mountains, where the Parkes process replaced that

of Pattinson, the ores and smelting process remaining

practically the same :—

Pb.

Pattinson

Parkes

99-966200

99-983139

Cu.

0-015000

0-001413

Sb.

1-010000

0-005698

Bi.

none

none

0-000600

0-005487

0-002200

0-000460

Fe.

0-004000

0-002289

Zii.

o-ooiooo

0-000834

1-001000

0-000680

The reverberatory furnace commonly used for cupelling

goes by the name of the English cupelling furnace. H is

oblong, and has a fixed roof and a movable iron

upe ' hearth (test). Formerly the test was lined with

bone-ash; at present the hearth-material is a mixture of

crushed limestone and clay (3:1), or Portland cement,

either alone or mixed with crushed fire-brick; in a few

instances the lining has been made of burnt magnesite. In

the beginning of the operation enough argentiferous lead is

charged to fill the cavity of the test. After it has been

melted down and brought to a red heat, the blast, ad¬

mitted at the back, oxidizes the lead and drives the

litharge formed towards the front, where it is run off. At

the same time small bars of argentiferous lead, inserted at

the back, are slowly pushed forward, so that in melting down

they may replace the oxidized lead. Thus the level of the

lead is kept approximately constant, and the silver be¬

comes concentrated in the lead. In large works the silver-

lead alloy is removed when it contains 60-80 per cent,

silver, and the cupellation of the rich bullion from several

concentration furnaces is finished in a second furnace. At

the same time the silver is brought to the required degree

of fineness, usually by the use of nitre. In small works

the cupellation is finished in one furnace, and the resulting

low-grade silver fined in a plumbago crucible, either by

overheating in the presence of air, or by the addition of

silver sulphate to the melted silver, when air or sulphur tri¬

oxide and oxygen oxidize the impurities. The lead charged

contains about F5 per cent, lead if it comes from a

Pattinson plant, from 5-10 per cent, if from a Parkes

plant. In a test 7 feet by 4 feet 10 inches, and 4 inches

deep, about 6 tons of lead are cupelled in twenty-four hours.

A furnace is served by three men, working in eight-hours

shifts, and requires about 2 tons of coal, which corresponds

to about 110 gallons reduced oil, air being used as atomizer.

The loss in lead is about 5 per cent. The latest cupelling

furnaces have the general form of a reverberatory copper-

smelting furnace. The working door through which the

litharge is.run off lies under the flue which carries off the

products of combustion and the lead fumes, the lead is

charged, and the blast is admitted near the fire-bridge.

In the Pattinson process the argentiferous lead is melted

down in the central cast-iron kettle of a series 8-15,

placed one next to the other, each having a

process?0 caPaci-ty °f 9-15 tons and a separate fireplace.

The crystals of impoverished lead which fall

to the bottom, upon coaling the charge, are taken out with

a skimmer and discharged into the neighbouring kettle

(say to the right) until about two-thirds of the original

charge has been removed ; then the liquid enriched lead is

ladled into the kettle on the opposite side. To the kettle,

two-thirds full of crystals of lead, is now added lead of the

same tenor in silver, the whole is liquefied, and the cool¬

ing, crystallizing, skimming, and ladling are repeated. The

same is done with the kettle one-third filled with liquid

lead, and so on until the first kettle contains market lead,

the last cupelling lead. The intervening kettles contain

leads with silver contents ranging from above market to

below cupelling lead. The original Pattinson process has

been in many cases replaced by the Luce-Rozan process

(1870), which does away with arduous labour and attains

a more satisfactory crystallization. The plant consists of

two tilting oval metal pans (capacity 7 tons), one cylindrical

crystallizing pot (capacity 22 tons), with two discharging

spouts * and one steam inlet opening, two lead moulds

(capacity 3| tons), and a steam crane. Pans and pot are

heated from separate fireplaces. Supposing the pot to be

filled with melted lead to be treated, the fire is withdrawn

beneath and steam introduced. This cools and stirs the

lead when crystals begin to form. As soon as two-thirds of

the lead has separated out in the form of crystals, the steam

is shut off and the liquid lead drained off through the two

spouts into the moulds. The fire underneath the pot is

again started, the crystals are liquefied, and one of the two

pans, filled with melted lead, is tilted by means of the

crane and its contents poured into the pot. In the mean¬

time the lead in the moulds, which has solidified, is removed

with the crane and stacked to one side, until its turn comes

to be raised and charged into one of the pans. The

crystallization proper lasts one hour, the working of a

charge four hours, six charges being run in twenty-four

hours.

It is absolutely necessary for the success of the Parkes

process that the zinc and lead should contain only a small

amount of impurity. The spelter used must

therefore be of a good grade, and the lead is Parkes

usually first refined in a reverberatory furnace Process’

(the softening furnace) as described above. The capacity

of the furnace must be 10 per cent, greater than that

of the kettle into which the softened lead is tapped,

as the dross and skimmings formed amount to about

10 per cent, of the weight of the lead charged. The

kettle is spherical, and is suspended over a fireplace by

a broad rim resting on a wall; it is usually of cast-

iron. Most kettles at present hold 30 tons of lead; some,

however, have double that capacity. When zinc is placed

on the lead (heated to above the melting-point of zinc),

liquefied, and brought into intimate contact with the lead

Set display mode to:

![]() Universal Viewer |

Universal Viewer | ![]() Mirador |

Large image | Transcription

Mirador |

Large image | Transcription

Images and transcriptions on this page, including medium image downloads, may be used under the Creative Commons Attribution 4.0 International Licence unless otherwise stated. ![]()

| Encyclopaedia Britannica > New volumes of the Encyclopædia Britannica > Volume 30, K-MOR > (198) Page 174 |

|---|

| Permanent URL | https://digital.nls.uk/193570075 |

|---|

| Attribution and copyright: |

|

|---|---|

| Shelfmark | EB.18 |

|---|---|

| Description | Ten editions of 'Encyclopaedia Britannica', issued from 1768-1903, in 231 volumes. Originally issued in 100 weekly parts (3 volumes) between 1768 and 1771 by publishers: Colin Macfarquhar and Andrew Bell (Edinburgh); editor: William Smellie: engraver: Andrew Bell. Expanded editions in the 19th century featured more volumes and contributions from leading experts in their fields. Managed and published in Edinburgh up to the 9th edition (25 volumes, from 1875-1889); the 10th edition (1902-1903) re-issued the 9th edition, with 11 supplementary volumes. |

|---|---|

| Additional NLS resources: |

|