Encyclopaedia Britannica > Volume 3, Anatomy-Astronomy

(422) Page 414

Download files

Complete book:

Individual page:

Thumbnail gallery: Grid view | List view

414

Arch.

Effects of

cement

and fric¬

tion in

dome¬

vaulting.

The iron

bridge at

Sunder¬

land de¬

scribed.

ARCH.

course, and then a similar or a greater portion of a small¬

er sphere may spring from this course as a base. It also

bears being intersected by cylindrical vaultings in every

direction, and the intersections are exact circles, and al¬

ways have a pleasing effect. It also springs most grace¬

fully from the heads of small piers, or from the corners

of rooms of any polygonal shape; and the arches formed

by its intersections with the walls are always circular and

graceful, forming very handsome spandrels in every posi¬

tion. For these reasons Sir Christopher Wren employed

it in all his vaultings, and he has exhibited many beauti¬

ful varieties in the transepts and the aisles of St Paul s,

which are highly worthy of the observation of architects.

Nothing can be more graceful than the vaultings at the

ends of the north and south transepts, especially as fur¬

nished off in the fine inside view published by Gwynn and

Wale.

46. The connection of the parts arising from cement and

from friction has a great effect on dome-vaulting. In the

same way as in common arches and cylindrical vaulting, it

enables an overload on one place to break the dome in a

distant place. But the resistance to this effect is much

greater in dome-vaulting, because it operates all round

the overloaded part. Hence it happens that domes are

much less shattered by partial violence, such as the fall¬

ing of a bomb or the like. Large holes may be broken in

them without much affecting the rest; but, on the other

hand, it greatly diminishes the strength which should be

derived from the mutual pressure in the vertical joints.

Friction prevents the sliding in of the arch-stones, which

produces this mutual pressure in the vertical joints, except

in the very highest courses, and even there it greatly di¬

minishes it. These causes make a great change in the

form which gives the greatest strength ; and as their laws

of action are as yet but very imperfectly understood, it is

perhaps impossible, in the present state of our knowledge,

to determine this form with tolerable precision. We see

plainly, however, that it allows a greater deviation from

the best form than the other kind of vaulting, and domes

may be made to rise perpendicular to the horizon at the

base, although of no great thickness; a thing which must

not be attempted in a plain arch. The immense addition

of strength which may be derived from hooping largely

compensates for all defects; and there are hardly any

bounds to the extent to which a very thin dome-vaulting

may be carried when it is hooped or framed in the direc¬

tion of the horizontal courses. The roof of the Halle du

Bled at Paris is but a foot thick, and its diameter is more

than 200, yet it appears to have abundant strength. It

is, on the whole, a noble specimen of architecture.

47. We must not conclude this article without taking

notice of that magnificent and elegant arch erected in

cast iron at Wearmouth, near Sunderland, in the county

of Durham. The inventor and architect was Rowland

Burden, Esq.

This arch (of which a view is given at the article Bridge)

is a segment of a circle whose diameter is about 444 feet.

The span or chord of the arch is 236 feet, and its versed

sine or spring is 34 feet. It springs at the elevation of

60 feet from the surface of the river at low water, so that

vessels of 200 or perhaps 300 tons burden may pass under

it in the middle of the stream, and even 50 feet on each

side of it.

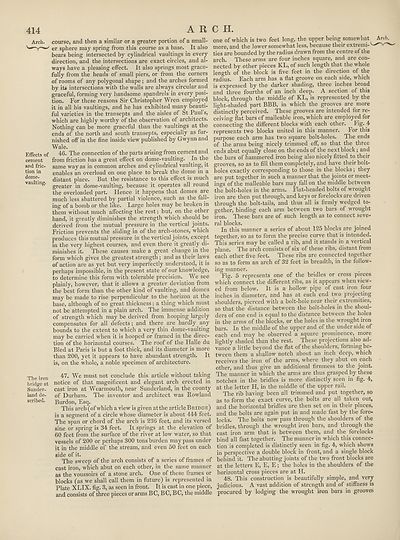

The sweep of the arch consists of a series of frames of

cast iron, which abut on each other, in the same manner

as the voussoirs of a stone arch. One of these frames or

blocks (as we shall call them in future) is represented in

Plate XLIX. fig. 3, as seen in front. It is cast in one piece,

and consists of three pieces or arms BC, BC, BC, the middle

one of which is two feet long, the upper being somewhat Arch,

more, and the lower somewhat less, because their extiemi-'v-^~v^

ties are bounded by the radius drawn from the centie of the

arch. These arms are four inches square, and are con¬

nected by other pieces KL, of such length that the whole

length of the block is five feet in the direction of the

radius. Each arm has a flat groove on each side, which

is expressed by the darker shading, three inches broad

and three fourths of an inch deep. A section of this

block, through the middle of KL, is represented by the

light-shaded part BBB, in which the grooves are more

distinctly perceived. These grooves are intended for re¬

ceiving flat bars of malleable iron, which are employed for

connecting the different blocks with each other. Fig. 4

represents two blocks united in this manner. For this

purpose each arm has two square bolt-holes. The ends

of the arms being nicely trimmed off, so that the three

ends abut equally close on the ends of the next block ; and

the bars of hammered iron being also nicely fitted to their

grooves, so as to fill them completely, and have their bolt¬

holes exactly corresponding to those in the blocks; they

are put together in such a manner that the joints or meet¬

ings of the malleable bars may fall on the middle between

the bolt-holes in the arms. Flat-headed bolts of wrought

iron are then put through, and keys or forelocks are driven

through the bolt-tails, and thus all is firmly wedged to¬

gether, binding each arm between two bars of wrought

iron. These bars are of such length as to connect seve¬

ral blocks.

In this manner a series of about 125 blocks are joined

together, so as to form the precise curve that is intended.

This series may be called a rib, and it stands in a vertical

plane. The arch consists of six of these ribs, distant from

each other five feet. These ribs are connected together

so as to form an arch of 32 feet in breadth, in the follow¬

ing manner.

Fig. 5 represents one of the bridles or cross pieces

which connect the different ribs, as it appears when view¬

ed from below. It is a hollow pipe of cast iron four

inches in diameter, and has at each end two projecting

shoulders, pierced with a bolt-hole near their extremities,

so that the distance between the bolt-holes in the shoul¬

ders of one end is equal to the distance between the holes

in the arms of the blocks, or the holes in the wrought iron

bars. In the middle of the upper and of the under side of

each end may be observed a square prominence, more

lightly shaded than the rest. These projections also ad¬

vance a little beyond the flat of the shoulders, forming be¬

tween them a shallow notch about an inch deep, which

receives the iron of the arms, where they abut on each

other, and thus give an additional firmness to the joint.

The manner in which the arms are thus grasped by these

notches in the bridles is more distinctly seen in fig. 4,

at the letter H, in the middle of the upper rail.

The rib having been all trimmed and put together, so

as to form the exact curve, the bolts are all taken out,

and the horizontal bridles are then set on in their places,

and the bolts are again put in and made fast by the fore¬

locks. The bolts now pass through the shoulders of the

bridles, through the wrought iron bars, and through the

cast iron arm that is between them, and the forelocks

bind all fast together. The manner in which this connec¬

tion is completed is distinctly seen in fig. 4, which shows

in perspective a double block in front, and a single block

behind it. The abutting joints of the two front blocks are

at the letters E, E, E; the holes in the shoulders of the

horizontal cross pieces are at H.

48. This construction is beautifully simple, and very

judicious. A vast addition of strength and of stiffness is

procured by lodging the wrought iron bars in grooves

Arch.

Effects of

cement

and fric¬

tion in

dome¬

vaulting.

The iron

bridge at

Sunder¬

land de¬

scribed.

ARCH.

course, and then a similar or a greater portion of a small¬

er sphere may spring from this course as a base. It also

bears being intersected by cylindrical vaultings in every

direction, and the intersections are exact circles, and al¬

ways have a pleasing effect. It also springs most grace¬

fully from the heads of small piers, or from the corners

of rooms of any polygonal shape; and the arches formed

by its intersections with the walls are always circular and

graceful, forming very handsome spandrels in every posi¬

tion. For these reasons Sir Christopher Wren employed

it in all his vaultings, and he has exhibited many beauti¬

ful varieties in the transepts and the aisles of St Paul s,

which are highly worthy of the observation of architects.

Nothing can be more graceful than the vaultings at the

ends of the north and south transepts, especially as fur¬

nished off in the fine inside view published by Gwynn and

Wale.

46. The connection of the parts arising from cement and

from friction has a great effect on dome-vaulting. In the

same way as in common arches and cylindrical vaulting, it

enables an overload on one place to break the dome in a

distant place. But the resistance to this effect is much

greater in dome-vaulting, because it operates all round

the overloaded part. Hence it happens that domes are

much less shattered by partial violence, such as the fall¬

ing of a bomb or the like. Large holes may be broken in

them without much affecting the rest; but, on the other

hand, it greatly diminishes the strength which should be

derived from the mutual pressure in the vertical joints.

Friction prevents the sliding in of the arch-stones, which

produces this mutual pressure in the vertical joints, except

in the very highest courses, and even there it greatly di¬

minishes it. These causes make a great change in the

form which gives the greatest strength ; and as their laws

of action are as yet but very imperfectly understood, it is

perhaps impossible, in the present state of our knowledge,

to determine this form with tolerable precision. We see

plainly, however, that it allows a greater deviation from

the best form than the other kind of vaulting, and domes

may be made to rise perpendicular to the horizon at the

base, although of no great thickness; a thing which must

not be attempted in a plain arch. The immense addition

of strength which may be derived from hooping largely

compensates for all defects; and there are hardly any

bounds to the extent to which a very thin dome-vaulting

may be carried when it is hooped or framed in the direc¬

tion of the horizontal courses. The roof of the Halle du

Bled at Paris is but a foot thick, and its diameter is more

than 200, yet it appears to have abundant strength. It

is, on the whole, a noble specimen of architecture.

47. We must not conclude this article without taking

notice of that magnificent and elegant arch erected in

cast iron at Wearmouth, near Sunderland, in the county

of Durham. The inventor and architect was Rowland

Burden, Esq.

This arch (of which a view is given at the article Bridge)

is a segment of a circle whose diameter is about 444 feet.

The span or chord of the arch is 236 feet, and its versed

sine or spring is 34 feet. It springs at the elevation of

60 feet from the surface of the river at low water, so that

vessels of 200 or perhaps 300 tons burden may pass under

it in the middle of the stream, and even 50 feet on each

side of it.

The sweep of the arch consists of a series of frames of

cast iron, which abut on each other, in the same manner

as the voussoirs of a stone arch. One of these frames or

blocks (as we shall call them in future) is represented in

Plate XLIX. fig. 3, as seen in front. It is cast in one piece,

and consists of three pieces or arms BC, BC, BC, the middle

one of which is two feet long, the upper being somewhat Arch,

more, and the lower somewhat less, because their extiemi-'v-^~v^

ties are bounded by the radius drawn from the centie of the

arch. These arms are four inches square, and are con¬

nected by other pieces KL, of such length that the whole

length of the block is five feet in the direction of the

radius. Each arm has a flat groove on each side, which

is expressed by the darker shading, three inches broad

and three fourths of an inch deep. A section of this

block, through the middle of KL, is represented by the

light-shaded part BBB, in which the grooves are more

distinctly perceived. These grooves are intended for re¬

ceiving flat bars of malleable iron, which are employed for

connecting the different blocks with each other. Fig. 4

represents two blocks united in this manner. For this

purpose each arm has two square bolt-holes. The ends

of the arms being nicely trimmed off, so that the three

ends abut equally close on the ends of the next block ; and

the bars of hammered iron being also nicely fitted to their

grooves, so as to fill them completely, and have their bolt¬

holes exactly corresponding to those in the blocks; they

are put together in such a manner that the joints or meet¬

ings of the malleable bars may fall on the middle between

the bolt-holes in the arms. Flat-headed bolts of wrought

iron are then put through, and keys or forelocks are driven

through the bolt-tails, and thus all is firmly wedged to¬

gether, binding each arm between two bars of wrought

iron. These bars are of such length as to connect seve¬

ral blocks.

In this manner a series of about 125 blocks are joined

together, so as to form the precise curve that is intended.

This series may be called a rib, and it stands in a vertical

plane. The arch consists of six of these ribs, distant from

each other five feet. These ribs are connected together

so as to form an arch of 32 feet in breadth, in the follow¬

ing manner.

Fig. 5 represents one of the bridles or cross pieces

which connect the different ribs, as it appears when view¬

ed from below. It is a hollow pipe of cast iron four

inches in diameter, and has at each end two projecting

shoulders, pierced with a bolt-hole near their extremities,

so that the distance between the bolt-holes in the shoul¬

ders of one end is equal to the distance between the holes

in the arms of the blocks, or the holes in the wrought iron

bars. In the middle of the upper and of the under side of

each end may be observed a square prominence, more

lightly shaded than the rest. These projections also ad¬

vance a little beyond the flat of the shoulders, forming be¬

tween them a shallow notch about an inch deep, which

receives the iron of the arms, where they abut on each

other, and thus give an additional firmness to the joint.

The manner in which the arms are thus grasped by these

notches in the bridles is more distinctly seen in fig. 4,

at the letter H, in the middle of the upper rail.

The rib having been all trimmed and put together, so

as to form the exact curve, the bolts are all taken out,

and the horizontal bridles are then set on in their places,

and the bolts are again put in and made fast by the fore¬

locks. The bolts now pass through the shoulders of the

bridles, through the wrought iron bars, and through the

cast iron arm that is between them, and the forelocks

bind all fast together. The manner in which this connec¬

tion is completed is distinctly seen in fig. 4, which shows

in perspective a double block in front, and a single block

behind it. The abutting joints of the two front blocks are

at the letters E, E, E; the holes in the shoulders of the

horizontal cross pieces are at H.

48. This construction is beautifully simple, and very

judicious. A vast addition of strength and of stiffness is

procured by lodging the wrought iron bars in grooves

Set display mode to:

![]() Universal Viewer |

Universal Viewer | ![]() Mirador |

Large image | Transcription

Mirador |

Large image | Transcription

Images and transcriptions on this page, including medium image downloads, may be used under the Creative Commons Attribution 4.0 International Licence unless otherwise stated. ![]()

| Encyclopaedia Britannica > Encyclopaedia Britannica > Volume 3, Anatomy-Astronomy > (422) Page 414 |

|---|

| Permanent URL | https://digital.nls.uk/193762834 |

|---|

| Attribution and copyright: |

|

|---|---|

| Shelfmark | EB.16 |

|---|---|

| Description | Ten editions of 'Encyclopaedia Britannica', issued from 1768-1903, in 231 volumes. Originally issued in 100 weekly parts (3 volumes) between 1768 and 1771 by publishers: Colin Macfarquhar and Andrew Bell (Edinburgh); editor: William Smellie: engraver: Andrew Bell. Expanded editions in the 19th century featured more volumes and contributions from leading experts in their fields. Managed and published in Edinburgh up to the 9th edition (25 volumes, from 1875-1889); the 10th edition (1902-1903) re-issued the 9th edition, with 11 supplementary volumes. |

|---|---|

| Additional NLS resources: |

|