Medicine - Veterinary > Veterinary colleges and laboratories > Indian journal of veterinary science and animal husbandry > Volume 12, 1942 > Original articles > Nutritive value of alkali-treated cereal straws

(300) Page 266

Download files

Individual page:

Thumbnail gallery: Grid view | List view

266 The Nutritive Value of Alkali-treated Cereal Straws

The chopped material was thoroughly mixed and 170 gm. of oat and 200 gm.

of wheat and paddy straws respectively were weighed out in separate en-

amelled basins. To the straws, 8 times their weight of 1.25 per cent caustic

soda solution was added and the contents of the basins thoroughly mixed

with a flat wooden ladle. The straws were soaked in alkali for about 20 hours.

The wet straw was then squeezed against the side of the basin and the alkaline

liquor poured off into a separate vessel. About 45 to 50 per cent of the

volume of the original liquor could thus be recovered. Tap water was then

added to an amount a little over the volume lost in soaking. The ' alkaline

straw ' was thoroughly turned over in this fresh water and after standing for

15 minutes, as much as possible of the wash water was separated from the

straw and poured into the vessel containing the original liquor. The com-

bined volume of the liquor and wash water was approximately the same as that

of the alkali solution used for treating the quantity of straw weighed out.

The strength of the alkali in the combined mixture of original liquor and wash

water was determined. After the collection of the first wash water, the treat-

ed straw was transferred to a thoroughly cleaned laboratory sink which was

fitted with an overhead water tap. The outlet passage of the sink was covered

with a wire gauze netting and water was continuously sprinkled over the mass

of straw till the wash water was no longer alkaline. The treated straw was

then dried and analysed. It may be mentioned that the dry treated straw

of all three kinds was markedly changed in colour and texture, the products

being distinctly yellow, softer to the feel and finer in texture than the original

straws.

The results and discussion

(a) The alkali treatment of the straws and their subsequent washing

with water to remove the alkali caused a significant loss in the dry matter

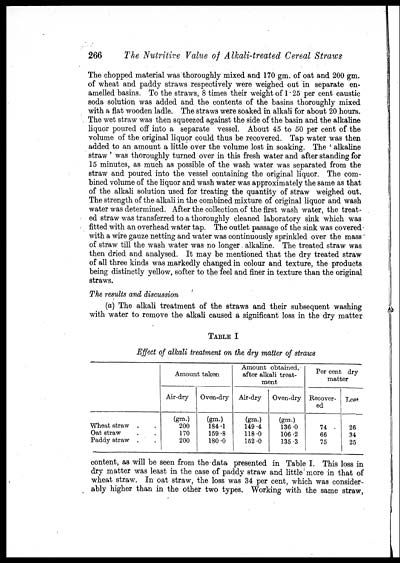

TABLE I

Effect of alkali treatment on the dry matter of straws

|

Amount taken |

Amount obtained, |

Per cent dry |

||||

|

Air-dry |

Oven-dry |

Air-dry |

Oven-dry |

Recover- |

Lost |

|

|

(gm.) |

(gm.) |

(gm.) |

(gm.) |

|||

|

Wheat straw . . |

200 |

184.1 |

149.4 |

136.0 |

74 |

26 |

|

Oat straw . . |

170 |

159.8 |

118.0 |

106.2 |

66 |

34 |

|

Paddy straw . . |

200 |

180.0 |

152.0 |

135.3 |

75 |

25 |

content, as will be seen from the data presented in Table I. This loss in

dry matter was least in the case of paddy straw and little more in that of

wheat straw. In oat straw, the loss was 34 per cent, which was consider-

ably higher than in the other two types. Working with the same straw,

Set display mode to: Large image | Zoom image | Transcription

Images and transcriptions on this page, including medium image downloads, may be used under the Creative Commons Attribution 4.0 International Licence unless otherwise stated. ![]()

| Permanent URL | https://digital.nls.uk/75317767 |

|---|

| Description | Covers articles from 1942. |

|---|