Download files

Complete book:

Individual page:

Thumbnail gallery: Grid view | List view

The First Long-Distance Steam Liners. 39

names, and as indicative of progress it may be stated that

they were each 440 ft. in length between perpendiculars,

52 ft. 6 in. in beam, 35 ft. in depth, with a gross tonnage of

7040 tons. But more important still, the coal consumption per

100 ton-miles was very much reduced. These later vessels are

also illustrated in the Plate facing page 101.

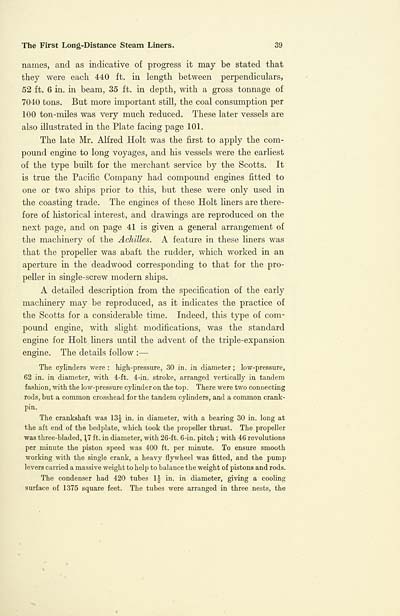

The late Mr. Alfred Holt was the first to apply the com-

pound engine to long voyages, and his vessels were the earliest

of the type built for the merchant service by the Scotts. It

is true the Pacific Company had compound engines fitted to

one or two ships prior to this, but these were only used in

the coasting trade. The engines of these Holt liners are there-

fore of historical interest, and drawings are reproduced on the

next page, and on page 41 is given a general arrangement of

the machinery of the Achilles. A feature in these liners was

that the propeller was abaft the rudder, which worked in an

aperture in the deadwood corresponding to that for the pro-

peller in single-screw modern ships.

A detailed description from the specification of the early

machinery may be reproduced, as it indicates the practice of

the Scotts for a considerable time. Indeed, this type of com-

pound engine, with slight modifications, was the standard

engine for Holt liners until the advent of the triple-expansion

engine. The details follow : —

The cylinders were: high-pressure, 30 in. in diameter; low-pressure,

62 in. in diameter, with 4-ft. 4-in. stroke, arranged vertically in tandem

fashion, with the low-pressure cylinder on the top. There were two connecting

rods, but a common crosshead for the tandem cylinders, and a common crank-

pin.

The crankshaft was 13£ in. in diameter, with a bearing 30 in. long at

the aft end of the bedplate, which took the propeller thrust. The propeller

was three-bladed, ^7 ft. in diameter, with 26-ft. 6-in. pitch ; with 46 revolutions

per minute the piston speed was 400 ft. per minute. To ensure smooth

working with the single crank, a heavy flywheel was fitted, and the pump

levers carried a massive weight to help to balance the weight of pistons and rods.

The condenser had 420 tubes 1| in. in diameter, giving a cooling

surface of 1375 square feet. The tubes were arranged in three nests, the

names, and as indicative of progress it may be stated that

they were each 440 ft. in length between perpendiculars,

52 ft. 6 in. in beam, 35 ft. in depth, with a gross tonnage of

7040 tons. But more important still, the coal consumption per

100 ton-miles was very much reduced. These later vessels are

also illustrated in the Plate facing page 101.

The late Mr. Alfred Holt was the first to apply the com-

pound engine to long voyages, and his vessels were the earliest

of the type built for the merchant service by the Scotts. It

is true the Pacific Company had compound engines fitted to

one or two ships prior to this, but these were only used in

the coasting trade. The engines of these Holt liners are there-

fore of historical interest, and drawings are reproduced on the

next page, and on page 41 is given a general arrangement of

the machinery of the Achilles. A feature in these liners was

that the propeller was abaft the rudder, which worked in an

aperture in the deadwood corresponding to that for the pro-

peller in single-screw modern ships.

A detailed description from the specification of the early

machinery may be reproduced, as it indicates the practice of

the Scotts for a considerable time. Indeed, this type of com-

pound engine, with slight modifications, was the standard

engine for Holt liners until the advent of the triple-expansion

engine. The details follow : —

The cylinders were: high-pressure, 30 in. in diameter; low-pressure,

62 in. in diameter, with 4-ft. 4-in. stroke, arranged vertically in tandem

fashion, with the low-pressure cylinder on the top. There were two connecting

rods, but a common crosshead for the tandem cylinders, and a common crank-

pin.

The crankshaft was 13£ in. in diameter, with a bearing 30 in. long at

the aft end of the bedplate, which took the propeller thrust. The propeller

was three-bladed, ^7 ft. in diameter, with 26-ft. 6-in. pitch ; with 46 revolutions

per minute the piston speed was 400 ft. per minute. To ensure smooth

working with the single crank, a heavy flywheel was fitted, and the pump

levers carried a massive weight to help to balance the weight of pistons and rods.

The condenser had 420 tubes 1| in. in diameter, giving a cooling

surface of 1375 square feet. The tubes were arranged in three nests, the

Set display mode to:

![]() Universal Viewer |

Universal Viewer | ![]() Mirador |

Large image | Transcription

Mirador |

Large image | Transcription

Images and transcriptions on this page, including medium image downloads, may be used under the Creative Commons Attribution 4.0 International Licence unless otherwise stated. ![]()

| Histories of Scottish families > Two centuries of shipbuilding by the Scotts at Greenock > (87) Page 39 |

|---|

| Permanent URL | https://digital.nls.uk/95739707 |

|---|

| Description | A selection of almost 400 printed items relating to the history of Scottish families, mostly dating from the 19th and early 20th centuries. Includes memoirs, genealogies and clan histories, with a few produced by emigrant families. The earliest family history goes back to AD 916. |

|---|