New volumes of the Encyclopædia Britannica > Volume 30, K-MOR

(477) Page 447

Download files

Complete book:

Individual page:

Thumbnail gallery: Grid view | List view

MAGNETISM

447

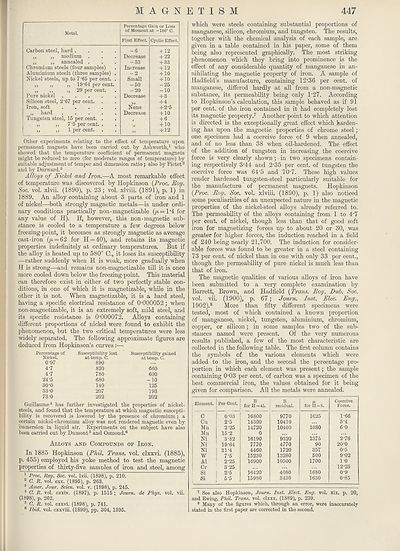

Metal.

Percentage Gain or Loss

of Moment at -186° C.

First Effect. Cyclic Effect.

Carbon steel, hard .

,, ,, medium

,, ,, annealed .

Chromium steels (four samples)

Aluminium steels (three samples)

Nickel steels, up to 7'65 per cent.

,, ,, ,, 19'64 per cent.

,, ,, ,, 29 per cent.

Pure nickel

Silicon steel, 2‘67 per cent.

Iron, soft

,, hard

Tungsten steel, 15 per cent.

. ,, ,, 7'5 per cent.

,, ,, 1 per cent.

-6

Decrease

-33

Increase

-2

Small

-50

-20

Decrease

99

None

Decrease

+ 12

+ 22

+ 33

+ 12

+ 10

+ 10

-25

-10

+ 3

+ 4

+ 2-5

+ 10

+ 6

+ 10

+ 12

Other experiments relating to the effect of temperature upon

permanent magnets have been carried out by Ashworth,1 who

showed that the temperature coefficient of permanent magnets

might be reduced to zero (for moderate ranges of temperature) by

suitable adjustment of temper and dimension ratio; also by Pictet2

and by Durward.3

Alloys of Nickel and Iron.—A most remarkable effect

of temperature was discovered by Hopkinson (fProc. Roy.

Soc. vol. xlvii. (1890), p. 23; vol. xlviii. (1891), p. 1) in

1889. An alloy containing about 3 parts of iron and 1

of nickel—both strongly magnetic metals—is under ordi¬

nary conditions practically non-magnetizable (//.= !’4 for

any value of H). If, however, this non-magnetic sub¬

stance is cooled to a temperature a few degrees below

freezing-point, it becomes as strongly magnetic as average

cast-iron (/x = 62 for H = 40), and retains its magnetic

properties indefinitely at ordinary temperatures. But if

the alloy is heated up to 580° C., it loses its susceptibility

—rather suddenly when H is weak, more gradually when

H is strong—-and remains non-magnetizable till it is once

more cooled down below the freezing-point. This material

can therefore exist in either of two perfectly stable con¬

ditions, in one of which it is magnetizable, while in the

other it is not. When magnetizable, it is a hard steel,

having a specific electrical resistance of 0’000052; when

non-magnetizable, it is an extremely soft, mild steel, and

its specific resistance is 0’000072. Alloys containing

different proportions of nickel were found to exhibit the

phenomenon, but the two critical temperatures were less

widely separated. The following approximate figures are

deduced from Hopkinson’s curves :—

Percentage of

Nickel.

0-97

4’7

4-7

24’5

30-0

33’0

73-0

Susceptibility lost

at temp. C.

890

820

780

680

140

207

202

Susceptibility gained

at temp. C.

660

600

-10

125

193

202

Guillaume4 has further investigated the properties of nickel-

steels, and found that the temperature at which magnetic suscepti¬

bility is recovered is lowered by the presence of chromium; a

certain nickel-chromium alloy was not rendered magnetic even by

immersion in liquid air. Experiments on the subject have also

been carried out by Dumont5 and Osmond.6

Alloys and Compounds of Iron.

In 1885 Hopkinson (Phil. Trans, vol. clxxvi. (1885),

p. 455) employed his yoke method to test the magnetic

properties of thirty-five samples of iron and steel, among

1 Proc. Roy. Soc. vol. Ixh. (1898), p. 210.

2 C. R. vol. cxx. (1895), p. 263.

3 Amer. Jour. Scien. vol. v. (1898), p. 245.

4 O. R. vol. cxxiv. (1897), p. 1515 ; Journ. de Phys. vol. vii.

(1898), p. 262.

5 C. R. vol. cxxvi. (1898), p. 741.

6 Ibid. vol. cxxviii. (1899), pp. 304, 1395.

which were steels containing substantial proportions of

manganese, silicon, chromium, and tungsten. The results,

together with the chemical analysis of each sample, are

given in a table contained in his paper, some of them

being also represented graphically. The most striking

phenomenon which they bring into prominence is the

effect of any considerable quantity of manganese in an¬

nihilating the magnetic property of iron. A sample of

Hadfield’s manufacture, containing 12’36 per cent, of

manganese, differed hardly at all from a non-magnetic

substance, its permeability being only 1’27. According

to Hopkinson’s calculation, this sample behaved as if 91

per cent, of the iron contained in it had completely lost

its magnetic property.7 Another point to which attention

is directed is the exceptionally great effect which harden¬

ing has upon the magnetic properties of chrome steel;

one specimen had a coercive force of 9 when annealed,

and of no less than 38 when oil-hardened. The effect

of the addition of tungsten in increasing the coercive

force is very clearly shown; in two specimens contain¬

ing respectively 3’44 and 2’35 per cent, of tungsten the

coercive force was 64’5 and 70’7. These high values

render hardened tungsten-steel particularly suitable for

the manufacture of permanent magnets. Hopkinson

(Proc. Roy. Soc. vol. xlviii. (1890), p. 1) also noticed

some peculiarities of an unexpected nature in the magnetic

properties of the nickel-steel alloys already referred to.

The permeability of the alloys containing from 1 to 4’7

per cent, of nickel, though less than that of good soft

iron for magnetizing forces up to about 20 or 30, was

greater for higher forces, the induction reached in a field

of 240 being nearly 21,700. The induction for consider¬

able forces was found to be greater in a steel containing

73 per cent, of nickel than in one with only 33 per cent.,

though the permeability of pure nickel is much less than

that of iron.

The magnetic qualities of various alloys of iron have

been submitted to a very complete examination by

Barrett, Brown, and Hadfield (Trans. Roy. Dub. Soc.

vol. vii. (1900), p. 67; Journ. Inst. Elec. Eng.,

1902).8 More than fifty different specimens were

tested, most of which contained a known proportion

of manganese, nickel, tungsten, aluminium, chromium,

copper, or silicon; in some samples two of the sub¬

stances named were present. Of the very numerous

results published, a few of the most characteristic are

collected in the following table. The first column contains

the symbols of the various elements which were

added to the iron, and the second the percentage pro¬

portion in which each element was present; the sample

containing 0’03 per cent, of carbon was a specimen of the

best commercial iron, the values obtained for it being

given for comparison. All the metals were annealed.

Element.

C

Cu

Mn

Mn

Ni

Ni

Ni

W

A1

Cr

Si

Si

Per Cent.

0’03

2’5

2’25

15’2

3’82

19’64

31’4

7’5

2’25

3’25

2’5

5’5

B

for H=45.

16800

14300

14720

0

16190

7770

4460

15230

16900

16420

15980

B

residual.

9770

10410

10460

9320

4770

1720

13280

10500

4080

3430

1625

1080

1375

90

357

500

1700

1680

1630

Coercive

Force.

1’66

5’4

6’0

2’76

20’0

0’5

9’02

10

12’25

0-9

0-85

7 See also Hopkinson, Journ. Inst. Elect. Eng. vol. xix. p. 20,

and Ewing, Phil. Trans, vol. clxxx. (1889), p. 239.

8 Many of the figures which, through an error, were inaccurately

stated in the first paper are corrected in the second.

447

Metal.

Percentage Gain or Loss

of Moment at -186° C.

First Effect. Cyclic Effect.

Carbon steel, hard .

,, ,, medium

,, ,, annealed .

Chromium steels (four samples)

Aluminium steels (three samples)

Nickel steels, up to 7'65 per cent.

,, ,, ,, 19'64 per cent.

,, ,, ,, 29 per cent.

Pure nickel

Silicon steel, 2‘67 per cent.

Iron, soft

,, hard

Tungsten steel, 15 per cent.

. ,, ,, 7'5 per cent.

,, ,, 1 per cent.

-6

Decrease

-33

Increase

-2

Small

-50

-20

Decrease

99

None

Decrease

+ 12

+ 22

+ 33

+ 12

+ 10

+ 10

-25

-10

+ 3

+ 4

+ 2-5

+ 10

+ 6

+ 10

+ 12

Other experiments relating to the effect of temperature upon

permanent magnets have been carried out by Ashworth,1 who

showed that the temperature coefficient of permanent magnets

might be reduced to zero (for moderate ranges of temperature) by

suitable adjustment of temper and dimension ratio; also by Pictet2

and by Durward.3

Alloys of Nickel and Iron.—A most remarkable effect

of temperature was discovered by Hopkinson (fProc. Roy.

Soc. vol. xlvii. (1890), p. 23; vol. xlviii. (1891), p. 1) in

1889. An alloy containing about 3 parts of iron and 1

of nickel—both strongly magnetic metals—is under ordi¬

nary conditions practically non-magnetizable (//.= !’4 for

any value of H). If, however, this non-magnetic sub¬

stance is cooled to a temperature a few degrees below

freezing-point, it becomes as strongly magnetic as average

cast-iron (/x = 62 for H = 40), and retains its magnetic

properties indefinitely at ordinary temperatures. But if

the alloy is heated up to 580° C., it loses its susceptibility

—rather suddenly when H is weak, more gradually when

H is strong—-and remains non-magnetizable till it is once

more cooled down below the freezing-point. This material

can therefore exist in either of two perfectly stable con¬

ditions, in one of which it is magnetizable, while in the

other it is not. When magnetizable, it is a hard steel,

having a specific electrical resistance of 0’000052; when

non-magnetizable, it is an extremely soft, mild steel, and

its specific resistance is 0’000072. Alloys containing

different proportions of nickel were found to exhibit the

phenomenon, but the two critical temperatures were less

widely separated. The following approximate figures are

deduced from Hopkinson’s curves :—

Percentage of

Nickel.

0-97

4’7

4-7

24’5

30-0

33’0

73-0

Susceptibility lost

at temp. C.

890

820

780

680

140

207

202

Susceptibility gained

at temp. C.

660

600

-10

125

193

202

Guillaume4 has further investigated the properties of nickel-

steels, and found that the temperature at which magnetic suscepti¬

bility is recovered is lowered by the presence of chromium; a

certain nickel-chromium alloy was not rendered magnetic even by

immersion in liquid air. Experiments on the subject have also

been carried out by Dumont5 and Osmond.6

Alloys and Compounds of Iron.

In 1885 Hopkinson (Phil. Trans, vol. clxxvi. (1885),

p. 455) employed his yoke method to test the magnetic

properties of thirty-five samples of iron and steel, among

1 Proc. Roy. Soc. vol. Ixh. (1898), p. 210.

2 C. R. vol. cxx. (1895), p. 263.

3 Amer. Jour. Scien. vol. v. (1898), p. 245.

4 O. R. vol. cxxiv. (1897), p. 1515 ; Journ. de Phys. vol. vii.

(1898), p. 262.

5 C. R. vol. cxxvi. (1898), p. 741.

6 Ibid. vol. cxxviii. (1899), pp. 304, 1395.

which were steels containing substantial proportions of

manganese, silicon, chromium, and tungsten. The results,

together with the chemical analysis of each sample, are

given in a table contained in his paper, some of them

being also represented graphically. The most striking

phenomenon which they bring into prominence is the

effect of any considerable quantity of manganese in an¬

nihilating the magnetic property of iron. A sample of

Hadfield’s manufacture, containing 12’36 per cent, of

manganese, differed hardly at all from a non-magnetic

substance, its permeability being only 1’27. According

to Hopkinson’s calculation, this sample behaved as if 91

per cent, of the iron contained in it had completely lost

its magnetic property.7 Another point to which attention

is directed is the exceptionally great effect which harden¬

ing has upon the magnetic properties of chrome steel;

one specimen had a coercive force of 9 when annealed,

and of no less than 38 when oil-hardened. The effect

of the addition of tungsten in increasing the coercive

force is very clearly shown; in two specimens contain¬

ing respectively 3’44 and 2’35 per cent, of tungsten the

coercive force was 64’5 and 70’7. These high values

render hardened tungsten-steel particularly suitable for

the manufacture of permanent magnets. Hopkinson

(Proc. Roy. Soc. vol. xlviii. (1890), p. 1) also noticed

some peculiarities of an unexpected nature in the magnetic

properties of the nickel-steel alloys already referred to.

The permeability of the alloys containing from 1 to 4’7

per cent, of nickel, though less than that of good soft

iron for magnetizing forces up to about 20 or 30, was

greater for higher forces, the induction reached in a field

of 240 being nearly 21,700. The induction for consider¬

able forces was found to be greater in a steel containing

73 per cent, of nickel than in one with only 33 per cent.,

though the permeability of pure nickel is much less than

that of iron.

The magnetic qualities of various alloys of iron have

been submitted to a very complete examination by

Barrett, Brown, and Hadfield (Trans. Roy. Dub. Soc.

vol. vii. (1900), p. 67; Journ. Inst. Elec. Eng.,

1902).8 More than fifty different specimens were

tested, most of which contained a known proportion

of manganese, nickel, tungsten, aluminium, chromium,

copper, or silicon; in some samples two of the sub¬

stances named were present. Of the very numerous

results published, a few of the most characteristic are

collected in the following table. The first column contains

the symbols of the various elements which were

added to the iron, and the second the percentage pro¬

portion in which each element was present; the sample

containing 0’03 per cent, of carbon was a specimen of the

best commercial iron, the values obtained for it being

given for comparison. All the metals were annealed.

Element.

C

Cu

Mn

Mn

Ni

Ni

Ni

W

A1

Cr

Si

Si

Per Cent.

0’03

2’5

2’25

15’2

3’82

19’64

31’4

7’5

2’25

3’25

2’5

5’5

B

for H=45.

16800

14300

14720

0

16190

7770

4460

15230

16900

16420

15980

B

residual.

9770

10410

10460

9320

4770

1720

13280

10500

4080

3430

1625

1080

1375

90

357

500

1700

1680

1630

Coercive

Force.

1’66

5’4

6’0

2’76

20’0

0’5

9’02

10

12’25

0-9

0-85

7 See also Hopkinson, Journ. Inst. Elect. Eng. vol. xix. p. 20,

and Ewing, Phil. Trans, vol. clxxx. (1889), p. 239.

8 Many of the figures which, through an error, were inaccurately

stated in the first paper are corrected in the second.

Set display mode to:

![]() Universal Viewer |

Universal Viewer | ![]() Mirador |

Large image | Transcription

Mirador |

Large image | Transcription

Images and transcriptions on this page, including medium image downloads, may be used under the Creative Commons Attribution 4.0 International Licence unless otherwise stated. ![]()

| Encyclopaedia Britannica > New volumes of the Encyclopædia Britannica > Volume 30, K-MOR > (477) Page 447 |

|---|

| Permanent URL | https://digital.nls.uk/193573702 |

|---|

| Attribution and copyright: |

|

|---|---|

| Shelfmark | EB.18 |

|---|---|

| Description | Ten editions of 'Encyclopaedia Britannica', issued from 1768-1903, in 231 volumes. Originally issued in 100 weekly parts (3 volumes) between 1768 and 1771 by publishers: Colin Macfarquhar and Andrew Bell (Edinburgh); editor: William Smellie: engraver: Andrew Bell. Expanded editions in the 19th century featured more volumes and contributions from leading experts in their fields. Managed and published in Edinburgh up to the 9th edition (25 volumes, from 1875-1889); the 10th edition (1902-1903) re-issued the 9th edition, with 11 supplementary volumes. |

|---|---|

| Additional NLS resources: |

|