New volumes of the Encyclopædia Britannica > Volume 30, K-MOR

(466) Page 436

Download files

Complete book:

Individual page:

Thumbnail gallery: Grid view | List view

MAGNETISM

436

differ from and resemble one another as regards their

magnetic properties. Curves of magnetization (which

express the relation of I to H) have a close resemblance

to those of induction; and indeed, since B = H + 47tI, and

47tI (except in extreme fields) greatly exceeds H in numerical

value, we may generally, without serious error, put I = B/47T,

and transform curves of induction into curves of magnetiza¬

tion by merely altering the scale to which the ordinates

are referred. A scale for the approximate transformation

for the curves in Fig. 12 is given at the right-hand side of

the diagram, the greatest error introduced by neglecting

H/47T not exceeding 0‘6 per cent. A study of such curves

as these reveals the fact that there are three distinct

stages in the process of magnetization. During the first

stage, when the magnetizing force is small, the magnet¬

ization (or the induction) increases rather slowly with

increasing force; this is well shown by the nickel curve

in the diagram, but the effect would be no less con¬

spicuous in the iron curve if the abscissae were plotted to

a larger scale. During the second stage small increments

of magnetizing force are attended by relatively large incre¬

ments of magnetization, as is indicated by the steep

ascent of the curve. Then the curve bends over, forming

what is often called a “knee,” and a third stage is entered

upon, during which a considerable increase of magnetizing

force has little further effect upon the magnetization.

When in this condition the metal is popularly said to be

“ saturated.” Under increasing magnetizing forces, greatly

exceeding those comprised within the limits of the diagram,

the magnetization does practically reach a limit, the

maximum value being attained with a magnetizing force

of less than 2000 for wrought iron and nickel, and less

than 4000 for cast iron and cobalt. The induction, how¬

ever, continues to increase indefinitely, though very slowly.

These observations have an important bearing upon the

molecular theory of magnetism, which will be referred

to later.

Curves of Permeability and of Susceptibility.—The

relations of y ( = B/H) to B, and of k ( = I/H) to I, may

be instructively exhibited by means of curves like those

constructed by Rowland (see Ency. Brit., Magnetism,

vol. xv. p. 256). Recent experiments show that if the

magnetizing force is carried far enough, the permeability

curve always becomes convex to the horizontal axis,

instead of meeting it in the manner indicated in Rowland’s

diagrams. In Fig. 13 a curve given by an experiment in

which the highest magnetizing force was 585 is compared

with Rowland’s curve for iron (Bidwell, Proc. Roy. Soc. vol.

xl. (1886), p. 495). Rowland’s experiment was carried only

as far as the point marked X, corresponding to a magnet¬

izing force of 65 and an induction of nearly 17,000, In

the other experiment, though the magnetizing force was

further increased no less than ninefold, the induction

reached only 19,800. It is seen that soon after the limit

of Rowland’s observations is passed, the curve, instead of

continuing in an almost straight line to meet the horizontal

axis, bends off asymptotically, the ultimate value of the

permeability still being as much as OS'O.

Ballistic Method ivith Yoke.—Hopkinson {Phil. Trans.,

1885, part ii. p. 455) introduced a modification of the usual

ballistic arrangement which presents the following advan¬

tages :—(1) very considerable magnetizing forces can be

applied with ordinary means ; (2) the samples to be tested,

having the form of cylindrical bars, are more easily pre¬

pared than rings or wires; (3) the actual induction at any

time can be measured, and not only changes of induction.

On the other hand, a very high degree of accuracy is not

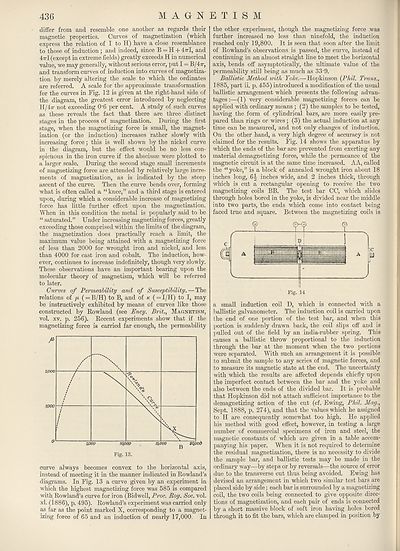

claimed for the results. Fig. 14 shows the apparatus by

which the ends of the bar are prevented from exerting any

material demagnetizing force, while the permeance of the

magnetic circuit is at the same time increased. AA, called

the “yoke,” is a block of annealed wrought iron about 18

inches long, 6^ inches wide, and 2 inches thick, through

which is cut a rectangular opening to receive the two

magnetizing coils BB. The test bar CC, which slides

through holes bored in the yoke, is divided near the middle

into two parts, the ends which come into contact being

faced true and square. Between the magnetizing coils is

a small induction coil D, which is connected with a

ballistic galvanometer. The induction coil is carried upon

the end of one portion of the test bar, and when this

portion is suddenly drawn back, the coil slips off and is

pulled out of the field by an india-rubber spring. This

causes a ballistic throw proportional to the induction

through the bar at the moment when the two portions

were separated. With such an arrangement it is possible

to submit the sample to any series of magnetic forces, and

to measure its magnetic state at the end. The uncertainty

with which the results are affected depends chieffy upon

the imperfect contact between the bar and the yoke and

also between the ends of the divided bar. It is probable

that Hopkinson did not attach sufficient importance to the

demagnetizing action of the cut (cf. Ewing, Phil. May.,

Sept. 1888, p. 274), and that the values which he assigned

to H are consequently somewhat too high. He applied

his method with good effect, however, in testing a large

number of commercial specimens of iron and steel, the

magnetic constants of which are given in a table accom¬

panying his paper. When it is not required to determine

the residual magnetization, there is no necessity to divide

the sample bar, and ballistic tests may be made in the

ordinary way—by steps or by reversals—the source of error

due to the transverse cut thus being avoided. Ewing has

devised an arrangement in which two similar test bars are

placed side by side; each bar is surrounded by a magnetizing

coil, the two coils being connected to give opposite direc¬

tions of magnetization, and each pair of ends is connected

by a short massive block of soft iron having holes bored

through it to fit the bars, which are clamped in position by

436

differ from and resemble one another as regards their

magnetic properties. Curves of magnetization (which

express the relation of I to H) have a close resemblance

to those of induction; and indeed, since B = H + 47tI, and

47tI (except in extreme fields) greatly exceeds H in numerical

value, we may generally, without serious error, put I = B/47T,

and transform curves of induction into curves of magnetiza¬

tion by merely altering the scale to which the ordinates

are referred. A scale for the approximate transformation

for the curves in Fig. 12 is given at the right-hand side of

the diagram, the greatest error introduced by neglecting

H/47T not exceeding 0‘6 per cent. A study of such curves

as these reveals the fact that there are three distinct

stages in the process of magnetization. During the first

stage, when the magnetizing force is small, the magnet¬

ization (or the induction) increases rather slowly with

increasing force; this is well shown by the nickel curve

in the diagram, but the effect would be no less con¬

spicuous in the iron curve if the abscissae were plotted to

a larger scale. During the second stage small increments

of magnetizing force are attended by relatively large incre¬

ments of magnetization, as is indicated by the steep

ascent of the curve. Then the curve bends over, forming

what is often called a “knee,” and a third stage is entered

upon, during which a considerable increase of magnetizing

force has little further effect upon the magnetization.

When in this condition the metal is popularly said to be

“ saturated.” Under increasing magnetizing forces, greatly

exceeding those comprised within the limits of the diagram,

the magnetization does practically reach a limit, the

maximum value being attained with a magnetizing force

of less than 2000 for wrought iron and nickel, and less

than 4000 for cast iron and cobalt. The induction, how¬

ever, continues to increase indefinitely, though very slowly.

These observations have an important bearing upon the

molecular theory of magnetism, which will be referred

to later.

Curves of Permeability and of Susceptibility.—The

relations of y ( = B/H) to B, and of k ( = I/H) to I, may

be instructively exhibited by means of curves like those

constructed by Rowland (see Ency. Brit., Magnetism,

vol. xv. p. 256). Recent experiments show that if the

magnetizing force is carried far enough, the permeability

curve always becomes convex to the horizontal axis,

instead of meeting it in the manner indicated in Rowland’s

diagrams. In Fig. 13 a curve given by an experiment in

which the highest magnetizing force was 585 is compared

with Rowland’s curve for iron (Bidwell, Proc. Roy. Soc. vol.

xl. (1886), p. 495). Rowland’s experiment was carried only

as far as the point marked X, corresponding to a magnet¬

izing force of 65 and an induction of nearly 17,000, In

the other experiment, though the magnetizing force was

further increased no less than ninefold, the induction

reached only 19,800. It is seen that soon after the limit

of Rowland’s observations is passed, the curve, instead of

continuing in an almost straight line to meet the horizontal

axis, bends off asymptotically, the ultimate value of the

permeability still being as much as OS'O.

Ballistic Method ivith Yoke.—Hopkinson {Phil. Trans.,

1885, part ii. p. 455) introduced a modification of the usual

ballistic arrangement which presents the following advan¬

tages :—(1) very considerable magnetizing forces can be

applied with ordinary means ; (2) the samples to be tested,

having the form of cylindrical bars, are more easily pre¬

pared than rings or wires; (3) the actual induction at any

time can be measured, and not only changes of induction.

On the other hand, a very high degree of accuracy is not

claimed for the results. Fig. 14 shows the apparatus by

which the ends of the bar are prevented from exerting any

material demagnetizing force, while the permeance of the

magnetic circuit is at the same time increased. AA, called

the “yoke,” is a block of annealed wrought iron about 18

inches long, 6^ inches wide, and 2 inches thick, through

which is cut a rectangular opening to receive the two

magnetizing coils BB. The test bar CC, which slides

through holes bored in the yoke, is divided near the middle

into two parts, the ends which come into contact being

faced true and square. Between the magnetizing coils is

a small induction coil D, which is connected with a

ballistic galvanometer. The induction coil is carried upon

the end of one portion of the test bar, and when this

portion is suddenly drawn back, the coil slips off and is

pulled out of the field by an india-rubber spring. This

causes a ballistic throw proportional to the induction

through the bar at the moment when the two portions

were separated. With such an arrangement it is possible

to submit the sample to any series of magnetic forces, and

to measure its magnetic state at the end. The uncertainty

with which the results are affected depends chieffy upon

the imperfect contact between the bar and the yoke and

also between the ends of the divided bar. It is probable

that Hopkinson did not attach sufficient importance to the

demagnetizing action of the cut (cf. Ewing, Phil. May.,

Sept. 1888, p. 274), and that the values which he assigned

to H are consequently somewhat too high. He applied

his method with good effect, however, in testing a large

number of commercial specimens of iron and steel, the

magnetic constants of which are given in a table accom¬

panying his paper. When it is not required to determine

the residual magnetization, there is no necessity to divide

the sample bar, and ballistic tests may be made in the

ordinary way—by steps or by reversals—the source of error

due to the transverse cut thus being avoided. Ewing has

devised an arrangement in which two similar test bars are

placed side by side; each bar is surrounded by a magnetizing

coil, the two coils being connected to give opposite direc¬

tions of magnetization, and each pair of ends is connected

by a short massive block of soft iron having holes bored

through it to fit the bars, which are clamped in position by

Set display mode to:

![]() Universal Viewer |

Universal Viewer | ![]() Mirador |

Large image | Transcription

Mirador |

Large image | Transcription

Images and transcriptions on this page, including medium image downloads, may be used under the Creative Commons Attribution 4.0 International Licence unless otherwise stated. ![]()

| Encyclopaedia Britannica > New volumes of the Encyclopædia Britannica > Volume 30, K-MOR > (466) Page 436 |

|---|

| Permanent URL | https://digital.nls.uk/193573559 |

|---|

| Attribution and copyright: |

|

|---|---|

| Shelfmark | EB.18 |

|---|---|

| Description | Ten editions of 'Encyclopaedia Britannica', issued from 1768-1903, in 231 volumes. Originally issued in 100 weekly parts (3 volumes) between 1768 and 1771 by publishers: Colin Macfarquhar and Andrew Bell (Edinburgh); editor: William Smellie: engraver: Andrew Bell. Expanded editions in the 19th century featured more volumes and contributions from leading experts in their fields. Managed and published in Edinburgh up to the 9th edition (25 volumes, from 1875-1889); the 10th edition (1902-1903) re-issued the 9th edition, with 11 supplementary volumes. |

|---|---|

| Additional NLS resources: |

|