Scotland > 1877 - Worrall's directory of the North-Eastern counties of Scotland, comprising the counties of Forfar, Fife, Kinross, Aberdeen, Banff, and Kincardine

(640)

Download files

Complete book:

Individual page:

Thumbnail gallery: Grid view | List view

68

ADVEETISEMENTS.

fWoEEALL'e

MlHMIir»Hhll'llUUIMIl»llHll«iuyilll«U

ARE INVALUABLE.

Ife

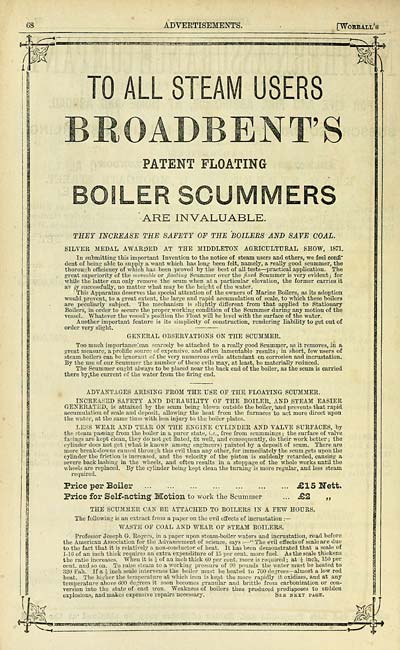

THEY INCREASE THE SAFETY OF THE BOILERS AND SAVE COAL.

SILVER MEDAL AWARDED AT THE MIDDLETON AGRICULTURAL SHOW, 1871.

In submitting this important Invention to the notice of steam users and others, we feel confi*

dent of being- able to supply a want wliich has long been felt, namely, a really good scummer, the

thorough efficiency of which has been proved by the best of all tests — practical application. The

gi'eat superiority of the moveable or floating Scummer over the fixed Scummer is very evident ; for

while tlie latter can only remove the scvim when at a particular elevation, the former carries it

av fy successfully, no matter what may be the height of the water.

This Apparatus deserves the special attention of the o^vners of Marine Boilers, as its adoption

would prevent, to a great extent, the large and rapid accumulation of scale, to which these boilerg

are peculiarly subject. The mechanism is slightly different from that applied to Stationary

Boilers, in order to secure the proper working condition of the Scummer during any motion of the

vessel. Whatever the vessel's position the Float wiU be level with the surface of the water.

Another important feature is its simplicity of construction, rendering liability to get out of

order very slight.

GENERAL OBSERVATIONS ON THE SCUMMER.

Too much importance!can scarcely be attached to a really good Scummer, as it removes, in a

great measure, a prolific source of expensive, and often lamentable results ; in short, few users of

steam boilers can be ignorant of the very numerous evils attendant on corrosion and incriistation.

By the use of our Scummer the number of these evils may, at least, be materially reduced.

The Scummer ought always to be placed near the back end of the boiler, as the scum is carried

there by^the current of the water from the firing end.

ADVANTAGES ARISING PROM THE USE OF THE FLOATING SCUMMER.

INCREASED SAFETY AND DURABILITY OF THE BOILER, AND STEAM EASIER

GENERATKD, is attained by the scum being bloivn outside the boiler, and prevents that rapid

accumulation of scale and deposit, allowing the heat from the furnaces to act more direct upon

the water, at the same time with less injury to the boiler plates.

LESS WEAR AND TEAR ON THE ENGINE CYLINDER AND VALVE SURFACES, by

the steam passing from the boiler in a purer state, i.e., free from scummings ; the surface of valve

facings are kept clean, they do not get fluted, fit well, and consequently, do their work better ; the

cylinder does not get (what is known among engineers) painted by a deposit of scum. There are

more break-downs caused through this e%dl than any other, for immediately the scum gets upon the

cylinder the friction is increased, and the velocity of the piston is suddenly retarded, causing a

severe back lashing in the wheels, and often results in a stoppage of the whole works until the

wheels are replaced. By the cylinder being kept clean the turning is more regular, and less steam

required.

... JglSNett.

... ^2 ■•

Price per Boiler

Price for Self-acting

[otion to work tlie Scummer

THE SCUMMER CAN BE ATTACHED TO BOILERS IN A FEW HOURS.

The follo-sving is an extract from a paper on the evil effects of incru.station : —

WASTE OF COAL AND WEAR OF STEAM BOILERS,

Professor Joseph G. Rogers, in a paper upon steam-boUer waters and incrastatiou, read before

the American Association for the Advancement of science, says : — "The evil effects of scale are due

to the fact that it is relatively a uon-condvictor of heat. It has been demonstrated that a scale of

1-16 of an inch thick requires an extra expenditure of 15 per cent, more fuel. As the scale thickens

the ratio increases. When it is i of an inch thick 60 per cent, more is raqiiired ; at } inch, 150 per

cent, and so on. To raise steam to a working pressure of 80 pounds the water must be lieated to

320 Fah. If a i inch scale intervenes the boiler must be heated to 700 degrees — almost a low rod

heat. The higher the temperature at which iron is kept the more rapidly it oxidizes, and at any

temperature above 600 degrees it soon becomes granular and brittle from carbonization or con-

version into the state of cast iron. Weakness of boilers thus produced predisposes to sudden

explosions, and makes expensive repaii's necessary. See next page.

wawi B »mmii i i;*t'ia i i.tM« ii iiiaaa jii iMa ii MiiuiaMiiii»uaji g''

ADVEETISEMENTS.

fWoEEALL'e

MlHMIir»Hhll'llUUIMIl»llHll«iuyilll«U

ARE INVALUABLE.

Ife

THEY INCREASE THE SAFETY OF THE BOILERS AND SAVE COAL.

SILVER MEDAL AWARDED AT THE MIDDLETON AGRICULTURAL SHOW, 1871.

In submitting this important Invention to the notice of steam users and others, we feel confi*

dent of being- able to supply a want wliich has long been felt, namely, a really good scummer, the

thorough efficiency of which has been proved by the best of all tests — practical application. The

gi'eat superiority of the moveable or floating Scummer over the fixed Scummer is very evident ; for

while tlie latter can only remove the scvim when at a particular elevation, the former carries it

av fy successfully, no matter what may be the height of the water.

This Apparatus deserves the special attention of the o^vners of Marine Boilers, as its adoption

would prevent, to a great extent, the large and rapid accumulation of scale, to which these boilerg

are peculiarly subject. The mechanism is slightly different from that applied to Stationary

Boilers, in order to secure the proper working condition of the Scummer during any motion of the

vessel. Whatever the vessel's position the Float wiU be level with the surface of the water.

Another important feature is its simplicity of construction, rendering liability to get out of

order very slight.

GENERAL OBSERVATIONS ON THE SCUMMER.

Too much importance!can scarcely be attached to a really good Scummer, as it removes, in a

great measure, a prolific source of expensive, and often lamentable results ; in short, few users of

steam boilers can be ignorant of the very numerous evils attendant on corrosion and incriistation.

By the use of our Scummer the number of these evils may, at least, be materially reduced.

The Scummer ought always to be placed near the back end of the boiler, as the scum is carried

there by^the current of the water from the firing end.

ADVANTAGES ARISING PROM THE USE OF THE FLOATING SCUMMER.

INCREASED SAFETY AND DURABILITY OF THE BOILER, AND STEAM EASIER

GENERATKD, is attained by the scum being bloivn outside the boiler, and prevents that rapid

accumulation of scale and deposit, allowing the heat from the furnaces to act more direct upon

the water, at the same time with less injury to the boiler plates.

LESS WEAR AND TEAR ON THE ENGINE CYLINDER AND VALVE SURFACES, by

the steam passing from the boiler in a purer state, i.e., free from scummings ; the surface of valve

facings are kept clean, they do not get fluted, fit well, and consequently, do their work better ; the

cylinder does not get (what is known among engineers) painted by a deposit of scum. There are

more break-downs caused through this e%dl than any other, for immediately the scum gets upon the

cylinder the friction is increased, and the velocity of the piston is suddenly retarded, causing a

severe back lashing in the wheels, and often results in a stoppage of the whole works until the

wheels are replaced. By the cylinder being kept clean the turning is more regular, and less steam

required.

... JglSNett.

... ^2 ■•

Price per Boiler

Price for Self-acting

[otion to work tlie Scummer

THE SCUMMER CAN BE ATTACHED TO BOILERS IN A FEW HOURS.

The follo-sving is an extract from a paper on the evil effects of incru.station : —

WASTE OF COAL AND WEAR OF STEAM BOILERS,

Professor Joseph G. Rogers, in a paper upon steam-boUer waters and incrastatiou, read before

the American Association for the Advancement of science, says : — "The evil effects of scale are due

to the fact that it is relatively a uon-condvictor of heat. It has been demonstrated that a scale of

1-16 of an inch thick requires an extra expenditure of 15 per cent, more fuel. As the scale thickens

the ratio increases. When it is i of an inch thick 60 per cent, more is raqiiired ; at } inch, 150 per

cent, and so on. To raise steam to a working pressure of 80 pounds the water must be lieated to

320 Fah. If a i inch scale intervenes the boiler must be heated to 700 degrees — almost a low rod

heat. The higher the temperature at which iron is kept the more rapidly it oxidizes, and at any

temperature above 600 degrees it soon becomes granular and brittle from carbonization or con-

version into the state of cast iron. Weakness of boilers thus produced predisposes to sudden

explosions, and makes expensive repaii's necessary. See next page.

wawi B »mmii i i;*t'ia i i.tM« ii iiiaaa jii iMa ii MiiuiaMiiii»uaji g''

Set display mode to: Large image | Transcription

Images and transcriptions on this page, including medium image downloads, may be used under the Creative Commons Attribution 4.0 International Licence unless otherwise stated. ![]()

| Permanent URL | https://digital.nls.uk/85204892 |

|---|

| Description | Directories of the whole, or large parts of, Scotland. |

|---|

| Description | Around 700 Scottish directories published annually by the Post Office or private publishers between 1773 and 1911. Most of Scotland covered, with a focus on Edinburgh, Glasgow, Dundee and Aberdeen. Most volumes include a general directory (A-Z by surname), street directory (A-Z by street) and trade directory (A-Z by trade). |

|---|