Britain: An official handbook > 1977

(246)

Download files

Complete book:

Individual page:

Thumbnail gallery: Grid view | List view

224

METAL

MANUFACTURE

Iron and Steel

Iron Castings

BRITAIN 1977: AN OFFICIAL HANDBOOK

In the following sections, relating to individual branches of industry in 1975,

employment statistics refer to numbers in Great Britain at June 1975) sales and

output figures are taken from the latest avadable Business Monitor and export

figures from the Overseas Trade Statistics. Unless otherwise stated, export and

manufacturers’ sales figures include parts.

Some sales figures are given in metric terms, where statistics for an industry

are normally published in this form. Conversion tables can be found on p. 45®*

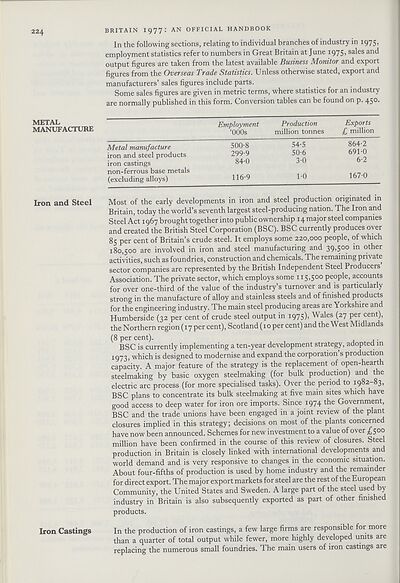

Metal manufacture

iron and steel products

iron castings

non-ferrous base metals

(excluding alloys)

Employment Production Exports

’000s million tonnes £ million

500-8 54-5 864-2

299-9 50-6 691-0

84-0 3-0 6-2

116-9 1-0 167-0

Most of the early developments in iron and steel production originated in

Britain, today the world’s seventh largest steel-producing nation. The Iron and

Steel Act 1967 brought together into public ownership 14 major steel companies

and created the British Steel Corporation (BSC). BSC currently produces over

85 per cent of Britain’s crude steel. It employs some 220,000 people, of which

180,500 are involved in iron and steel manufacturing and 39,500 in other

activities, such as foundries, construction and chemicals. The remaining private

sector companies are represented by the British Independent Steel Producers

Association. The private sector, which employs some 115,500 people, accounts

for over one-third of the value of the industry’s turnover and is particularly

strong in the manufacture of alloy and stainless steels and of finished products

for the engineering industry. The main steel producing areas are Yorkshire and

Humberside (32 per cent of crude steel output in 1975)) Wales (27 per cent),

the Northern region (17 per cent), Scotland (10 per cent) and the West Midlands

(8 per cent). .

BSC is currently implementing a ten-year development strategy, adopted in

1973, which is designed to modernise and expand the corporation s production

capacity. A major feature of the strategy is the replacement of open-hearth

steelmaking by basic oxygen steelmaking (for bulk production) and the

electric arc process (for more specialised tasks). Over the period to 1982-83,

BSC plans to concentrate its bulk steelmaking at five mam sites which have

good access to deep water for iron ore imports. Since 1974 the Government,

BSC and the trade unions have been engaged in a joint review of the plant

closures implied in this strategy; decisions on most of the plants concerned

have now been announced. Schemes for new investment to a value of over £$00

million have been confirmed in the course of this review of closures. Steel

production in Britain is closely linked with international developments and

world demand and is very responsive to changes in the economic situation.

About four-fifths of production is used by home industry and the remainder

for direct export. The major export markets for steel are the rest of the European

Community, the United States and Sweden. A large part of the steel used by

industry in Britain is also subsequently exported as part of other finished

products.

In the production of iron castings, a few large firms are responsible for more

than a quarter of total output while fewer, more highly developed units are

replacing the numerous small foundries. The main users of iron castings are

METAL

MANUFACTURE

Iron and Steel

Iron Castings

BRITAIN 1977: AN OFFICIAL HANDBOOK

In the following sections, relating to individual branches of industry in 1975,

employment statistics refer to numbers in Great Britain at June 1975) sales and

output figures are taken from the latest avadable Business Monitor and export

figures from the Overseas Trade Statistics. Unless otherwise stated, export and

manufacturers’ sales figures include parts.

Some sales figures are given in metric terms, where statistics for an industry

are normally published in this form. Conversion tables can be found on p. 45®*

Metal manufacture

iron and steel products

iron castings

non-ferrous base metals

(excluding alloys)

Employment Production Exports

’000s million tonnes £ million

500-8 54-5 864-2

299-9 50-6 691-0

84-0 3-0 6-2

116-9 1-0 167-0

Most of the early developments in iron and steel production originated in

Britain, today the world’s seventh largest steel-producing nation. The Iron and

Steel Act 1967 brought together into public ownership 14 major steel companies

and created the British Steel Corporation (BSC). BSC currently produces over

85 per cent of Britain’s crude steel. It employs some 220,000 people, of which

180,500 are involved in iron and steel manufacturing and 39,500 in other

activities, such as foundries, construction and chemicals. The remaining private

sector companies are represented by the British Independent Steel Producers

Association. The private sector, which employs some 115,500 people, accounts

for over one-third of the value of the industry’s turnover and is particularly

strong in the manufacture of alloy and stainless steels and of finished products

for the engineering industry. The main steel producing areas are Yorkshire and

Humberside (32 per cent of crude steel output in 1975)) Wales (27 per cent),

the Northern region (17 per cent), Scotland (10 per cent) and the West Midlands

(8 per cent). .

BSC is currently implementing a ten-year development strategy, adopted in

1973, which is designed to modernise and expand the corporation s production

capacity. A major feature of the strategy is the replacement of open-hearth

steelmaking by basic oxygen steelmaking (for bulk production) and the

electric arc process (for more specialised tasks). Over the period to 1982-83,

BSC plans to concentrate its bulk steelmaking at five mam sites which have

good access to deep water for iron ore imports. Since 1974 the Government,

BSC and the trade unions have been engaged in a joint review of the plant

closures implied in this strategy; decisions on most of the plants concerned

have now been announced. Schemes for new investment to a value of over £$00

million have been confirmed in the course of this review of closures. Steel

production in Britain is closely linked with international developments and

world demand and is very responsive to changes in the economic situation.

About four-fifths of production is used by home industry and the remainder

for direct export. The major export markets for steel are the rest of the European

Community, the United States and Sweden. A large part of the steel used by

industry in Britain is also subsequently exported as part of other finished

products.

In the production of iron castings, a few large firms are responsible for more

than a quarter of total output while fewer, more highly developed units are

replacing the numerous small foundries. The main users of iron castings are

Set display mode to:

![]() Universal Viewer |

Universal Viewer | ![]() Mirador |

Large image | Transcription

Mirador |

Large image | Transcription

The item on this page appears courtesy of Office for National Statistics and may be re-used under the Open Government Licence for Public Sector Information.

| Britain and UK handbooks > Britain: An official handbook > 1977 > (246) |

|---|

| Permanent URL | https://digital.nls.uk/205417382 |

|---|

| Attribution and copyright: |

|

|---|---|

| Description | 'Britain: An official handbook' was produced annually by the Central Office of Information from 1954-1998. There are 44 volumes available here to view. |

|---|---|

| Shelfmark | GII.11 |

| Description | Three titles produced by the British Government from 1954-2005 describing 'how Britain worked'. They are: 'Britain: An official handbook' (1954-1998), 'Britain: The official yearbook of the United Kingdom' (1999-2001), and 'UK: The official yearbook of the United Kingdom of Great Britain and Northern Ireland' (2002-2005). These 50 reports provide an overview of Britain's economic, social and cultural affairs, its environment, international relations, and the systems of government. They give an impartial summary of government policies and initiatives, and explain how public services are organised. |

|---|---|

| Additional NLS resources: |

|